Automatic Crack Length Measurements in Fatigue Testing

Plastic components subjected to cyclical loading cycles during their use can sometimes failure through fatigue crack formation. A plastic that shows good toughness in static testing may have brittle behavior when exposed to millions of fatigue cycles, particularly in parts with a sharp notch. Fatigue crack propagation testing helps to determine if a material is resistant to crack formation, and to compare different formulations of materials.

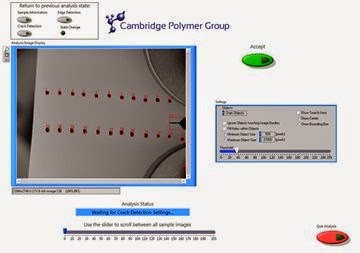

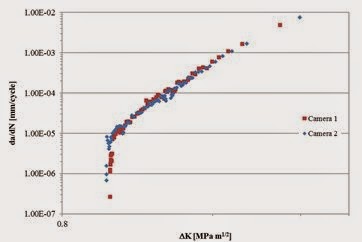

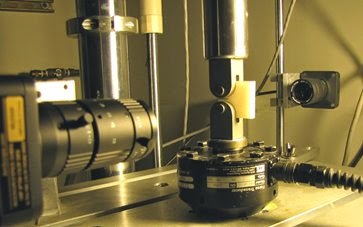

ASTM E647 describes the general protocol for fatigue crack propagation testing in materials using a pre-notched compact tensile specimen. The test requires simultaneous measurements of crack propagation after the application of tensile fatigue cycles. CPG engineers have developed an automated optical system that captures thousands of images of the propagating crack during the fatigue experiment from a dual camera system. The accompanying analysis software then determines the crack length in each image, outputting the da/dN vs. DK curve described in ASTM E647. The system provides a high density of data, in full compliance with E647, with greatly reduced labor.

More information on the system can be found here.

Contact CPG for more information on this system, which is available for purchase.

More information on the system can be found here.

Contact CPG for more information on this system, which is available for purchase.