Residual Monomers

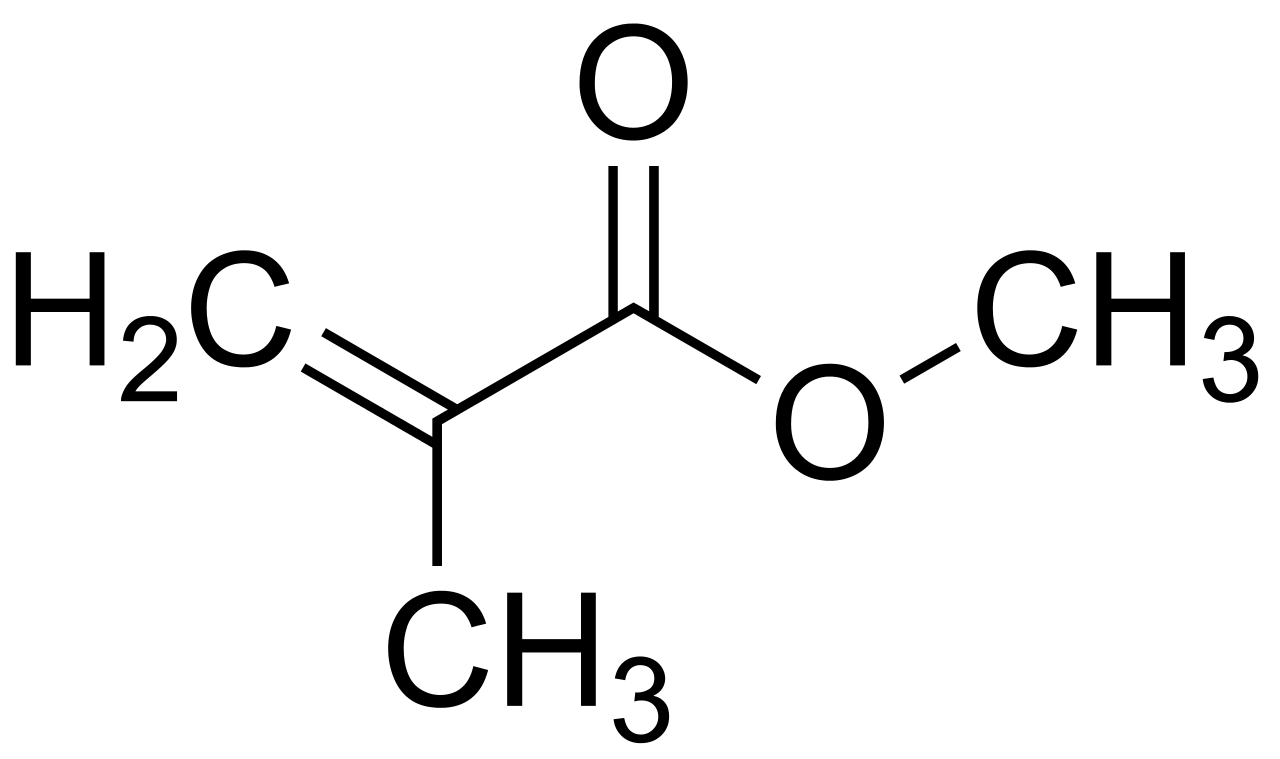

Polymers are synthesized from repeating monomer sub-units; however, polymerization efficiencies are rarely 100% and subsequent cleaning and refining steps are often unable to completely eliminate residual monomer content in finished resins or devices. Often these residual monomers represent hazardous compounds, the levels of which must be carefully controlled for both employee and end user safety.

For example, the monomer of polyacrylamide (widely used in water treatment and agricultural applications) is acrylamide—a neurotoxin. Some formulations of polycarbonate and epoxy resins employ bisphenol A (BPA) as a monomer unit and which has been found to exhibit hormone-mimicking properties. Presence of residual monomers may adversely impact a polymer system’s mechanical, rheological, or other functional properties.

Choosing the appropriate analytical technique for residual monomer analysis is critical for ensuring accurate quantitation and method sensitivity, specificity, and recovery from either the polymeric matrix or from complex end-use environment (cleaning system solutions, environmental samples, biological fluids/tissues, etc). CPG can assist in selecting the appropriate technique based on a detailed understanding of your polymer system chemistry, material processing workflow, and end use conditions.

RESIDUAL OLIGOMERS

In addition to residual monomer characterization, CPG also has experience studying the presence of residual oligomeric species, low molecular weight compounds representing a small number of monomers linked together (e.g. dimers, trimers, etc). The presence of such compounds may have significant impact on product safety and efficacy but may be missed in traditional residual monomer assays. Mass spectral analysis (e.g. using headspace GC-MS or LC-MS techniques) or high resolution GPC techniques, can identify and quantify such oligomeric species.

Contact CPG to see learn how we can work with your team. Example residual monomer application areas include:

- Adhesive systems, including systems cured “in-situ” e.g. biomedical adhesives

- Degradation product assessment

- Impact on mechanical, rheological, thermal, and chemical properties

- Oligomer analysis

- Method development, validation, and transfer

- Chromatographic Analysis – GC-MS, LC-MS, GPC