Impurity Characterization/

Contaminant Identification

Impurities present in pharmaceutical and medical device products may arise from raw input materials, reaction byproducts, or represent left over residual solvents or manufacturing processing aids. The potential presence and concentration of such compounds is typically considered during a risk assessment.

Unexpected and/or lot-to-lot dependent impurities or contaminants may impact API synthesis steps or medical device manufacturing stages by causing unexpected reactions in these processes. Such impurities or contaminants may also impact the ultimate stability and shelf life of the API or medical device components. Therefore, analysis and mitigation of potentially problematic species is of critical importance in a product development process.

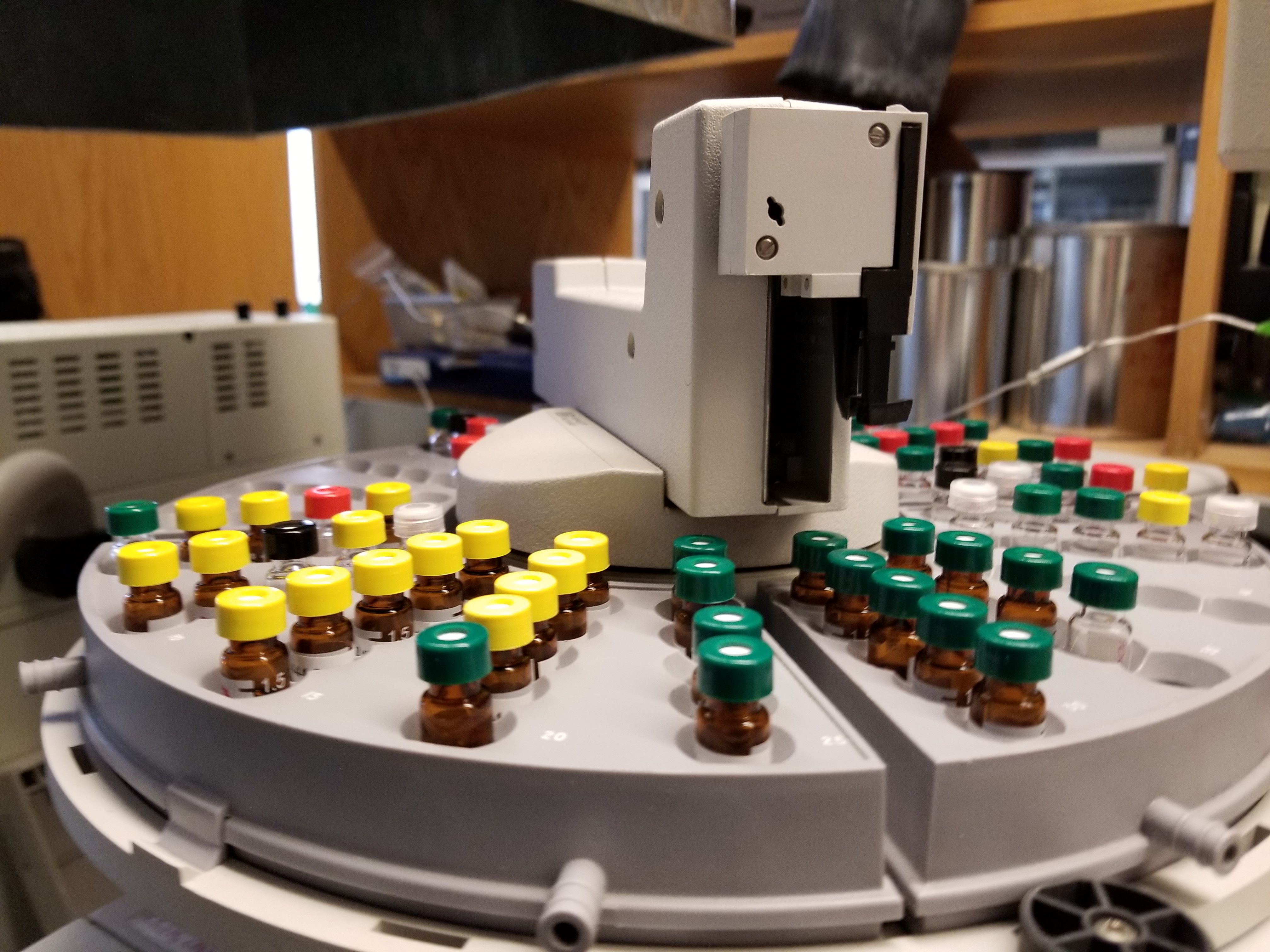

Cambridge Polymer Group has experience leveraging a variety of analytical techniques for the characterization of trace material impurities or contaminants, often down to parts-per-billion (ppb) levels. Analytical techniques typically include (but are not limited to) gas chromatography coupled to mass spectrometry (GC-MS) and high performance liquid chromatography (HPLC) coupled to mass spectrometry (LC-MS). Your materials may be tested by orthogonal chromatographic methods to ensure that no extra impurity peaks are “buried” under the main compound peak—and which may be therefore missed on the manufacturer’s certificate of analysis. CPG scientists’ expertise in mass spectrometry techniques allows for unknown identification and characterization of impurity structure even in a complex sample matrix. Polymer impurities or evidence of polymer degradation may be characterized by techniques such as Gel Permeation Chromatography (GPC).

Impurities and Contaminants: A Needle in the Haystack; Knowing the Context Makes the Haystack Smaller

Trace impurity/contaminant analysis requires careful consideration of the sample chemistry and processing conditions—CPG scientists will work with you to review such information, pinpoint potential problem areas as well as identify especially sensitive material properties or processing steps.

The workflows described here may be employed as part of a simple good/bad analysis as well as to evaluate the efficacy of processing and cleaning steps (while ensuring that the processing or cleaning contact materials are not themselves adversely impacting the product!).

Contact CPG to learn how our trace impurity/contaminant analysis capabilities may fit into your next project.