Filament stretching extensional rheometry

Most polymeric materials exhibit non-Newtonian behavior, meaning that their properties do not behave linearly, and are often strongly rate-dependent. This behavior is strikingly demonstrated in Silly Putty, which flows like a liquid a low deformation rates, and breaks like a brittle solid at high deformation rates. Non-Newtonian behavior in shear flow is often seen as shear-thinning, where the viscosity decreases with increasing shear rate. In contrast, when polymer materials are subjected to an extensional flow, such as that found in fiber spinning, blow molding, contraction flow, and some injection molding processes, the polymer chains are stretched out, resulting in increases in viscosity and elasticity that can reach several orders of magnitude. These properties changes can radically change the polymer's behavior in these processes, either beneficially or detrimentally. Extensional flow characterization will help predict this behavior and allow processes to determine optimal process conditions.

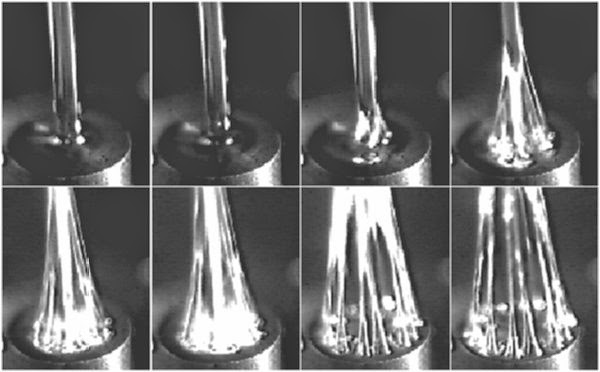

The best way to determine extensional flow properties is through filament stretching extensional rheometry. This technique has been around for several decades, although most extensional rheometers are home-made. Filament stretching extensional rheometers, or FiSERs, look similar to load frames used to determine the tensile properties of polymer solids. A set of motors stretches a small volume of fluid while simultaneously measuring the tensile force and cross-sectional area of the fluid strand. What makes this test challenging are the small forces and high rates of deformation typically required, along with a non-standard deformation profile. In the images above, a non-Newtonian fluid filament was stretched in a FiSER, and underwent an elastic instability at the endplate, causing the single filament to split into multiple filaments. This instability is discussed in greater detail in the following publication.

Cambridge Polymer Group has developed several FiSER systems in the past for clients, in areas ranging from polymer melts, food products, and polymer solutions. Each FiSER system is custom made based on client requirements.

More information on buying a FiSER

Several publications on FiSER testing of polymer materials are found here.

Application note on FiSER testing