Filler content in plastics

|

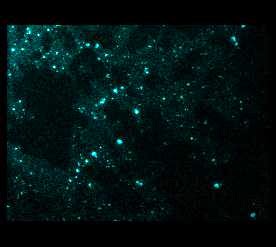

| Not the night sky, but rather an elemental map of filler in a polymer matrix. The bright spots are zirconium oxide in PMMA. |

Inorganic fillers are often added to thermoplastics to provide increased rigidity, hardness, impact strength, thermal conductivity, radiopacity, as well as reduced mold shrinkage. Filler, in the form of a powder, is normally compounded into the thermoplastic resin with an extruder, with filler contents ranging up to 60 wt.% depending on the application.

The degree of dispersion, identity, and quantity of filler can be determined with scanning electron microscopy with energy dispersive spectroscopy (SEM-EDS) and thermogravimetric analysis (TGA). SEM-EDS provides structural and elemental information about the polymer resin. TGA provides mass change in the sample as it is heated to high temperatures.

In the application note below, this analysis was performed on a filler in polymethyl methacrylate. The results shows that the resin contained approximately 10 wt.% zirconium oxide.

Link to the full application note.

Link to the full application note.