Consolidation Defects in UHMWPE

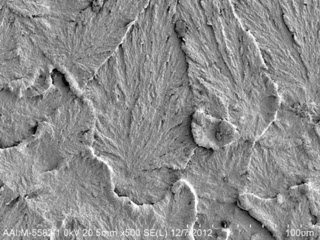

Ultra high molecular weight polyethylene (UHMWPE) is the most commonly used bearing surface in hip and knee arthroplasties. Due to its high molecular weight, UHMWPE cannot be injection molded or extruded with a screw extruder. Compression molding or ram extrusion are the two consolidation processes used for UHMWPE, whereby the combination of temperature and pressure sinter the flakes of UHMWPE together. These processes do not result in co-mingling of the UHMWPE powder, however, so that the original flakes can be readily seen in a cryo-fractured surface (see above). Regulators are interested in verify that consolidation defects, or voids, do not exist in the consolidated UHMWPE. These defects can result in crack formation and failure of the device if the defects are in sufficient quantity and size. SEM analysis of cryo-fractured surfaces is a commonly used technique to look for consolidation defects, along with optical microscopy of microtomed films of the material. Regulatory submissions usually require these analyses, comparing a new formulation of UHMWPE with a cleared and marketed formulation.