From Residues to Risk: Why Medical Device Cleaning Validation Matters in Biocompatibility Assessments

Webinar – October 15, 2025, 2 p.m. ET Register Here Ensuring medical device safety requires a coordinated approach across three critical domains: biocompatibility, cleanliness, and sterility. While each area has its own regulatory and testing requirements, they are deeply interconnected. Overlooking the relationship between these elements can increase patient risk and delay product approvals. This upcoming medical […]

Hydrogel Water Beads: For Farming Use Only

What Are Water Beads? “Water beads” are water-absorbent polymer beads that can swell over several hundreds of times their initial dry mass when placed in water, forming hydrogel beads. They are primarily marketed as agricultural products to act as humectants in soil, helping retain and slowly release water into the soil. Beyond farming, however, water […]

Material Deformulation: Because Ignorance Is NOT Bliss (Especially When Your Product Fails) Webinar

Webinar Date: September 17, 2:00 p.m. EDT Register Here When a product unexpectedly fails, performs below expectations, or does not meet safety standards, the cause often lies deep in the materials—or even in trace contaminants—you never knew were there. That’s where material deformulation becomes essential. Rather than building a product from scratch (formulation), deformulation is […]

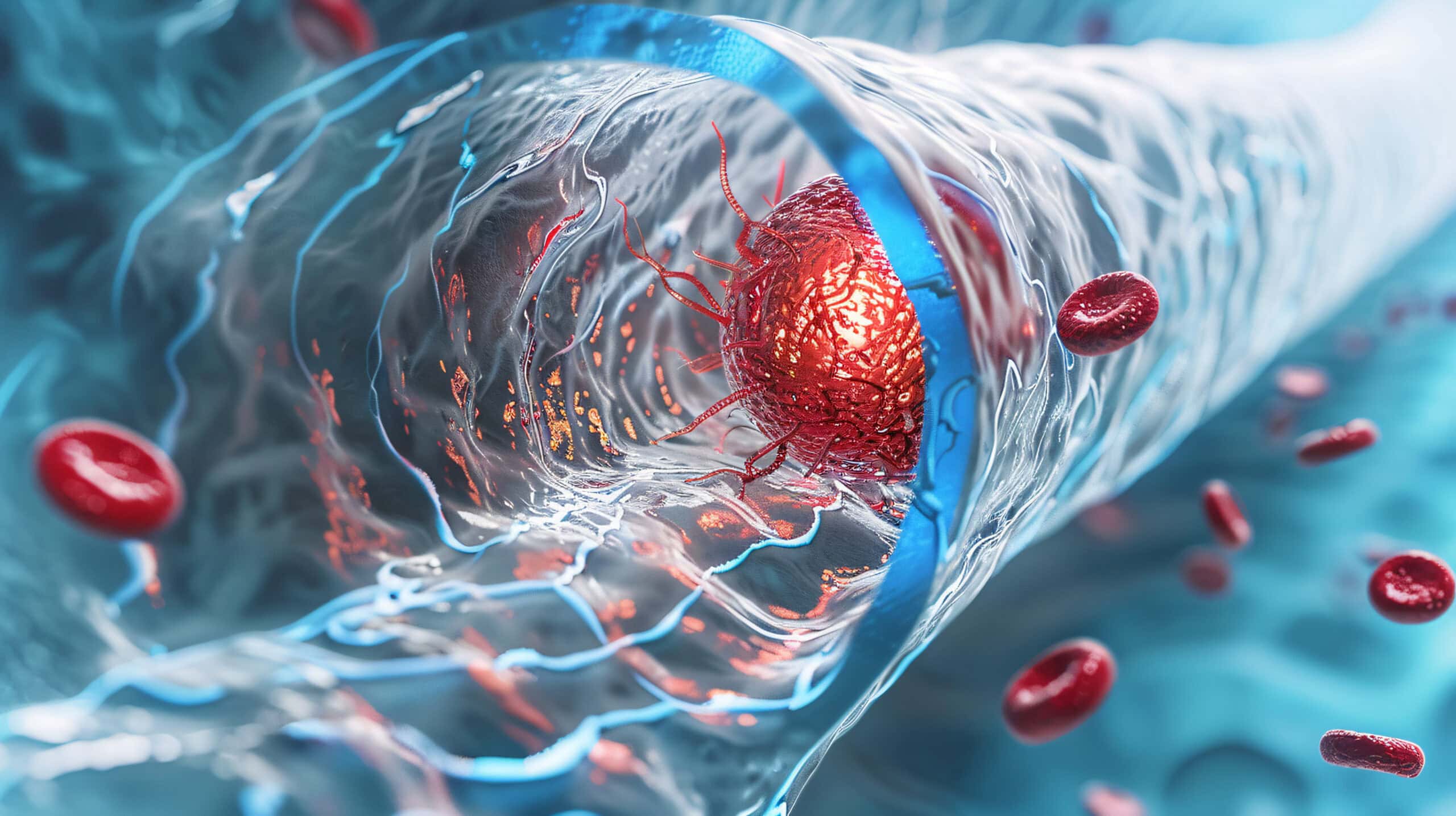

There’s More to Cutting Tissue Than You Think

In medical device development and surgical training, having a suitable test environment is essential for screening device concepts and reliably training surgeons. Traditionally, this process relied on excised animal or human cadaveric tissue—but the use of such tissue is problematic from both ethical and practical perspectives, including issues with stability and variability. Hydrogel systems now […]

Squeezing the Most Out of Medical Device Hydrogels Webinar

Wednesday, August 13, 2 p.m. EDT Hydrogels are rapidly transforming the medical device landscape, offering material properties that more closely emulate natural tissues than traditional rigid alternatives. In the upcoming webinar, “Squeezing the Most Out of Hydrogel Medical Devices,” Dr. Gavin Braithwaite will provide an in-depth perspective on how these unique polymers are advancing the […]

Flamingos Doing Vector Calculus

While we’ve previously celebrated the kitschy charm of plastic flamingos, today we turn our attention to the remarkable living birds and the science behind their mesmerizing feeding behaviors. With their beaks and most of their heads submerged near their feet, the birds stomp their feet in a rhythmic manner while chattering their beaks. But what […]

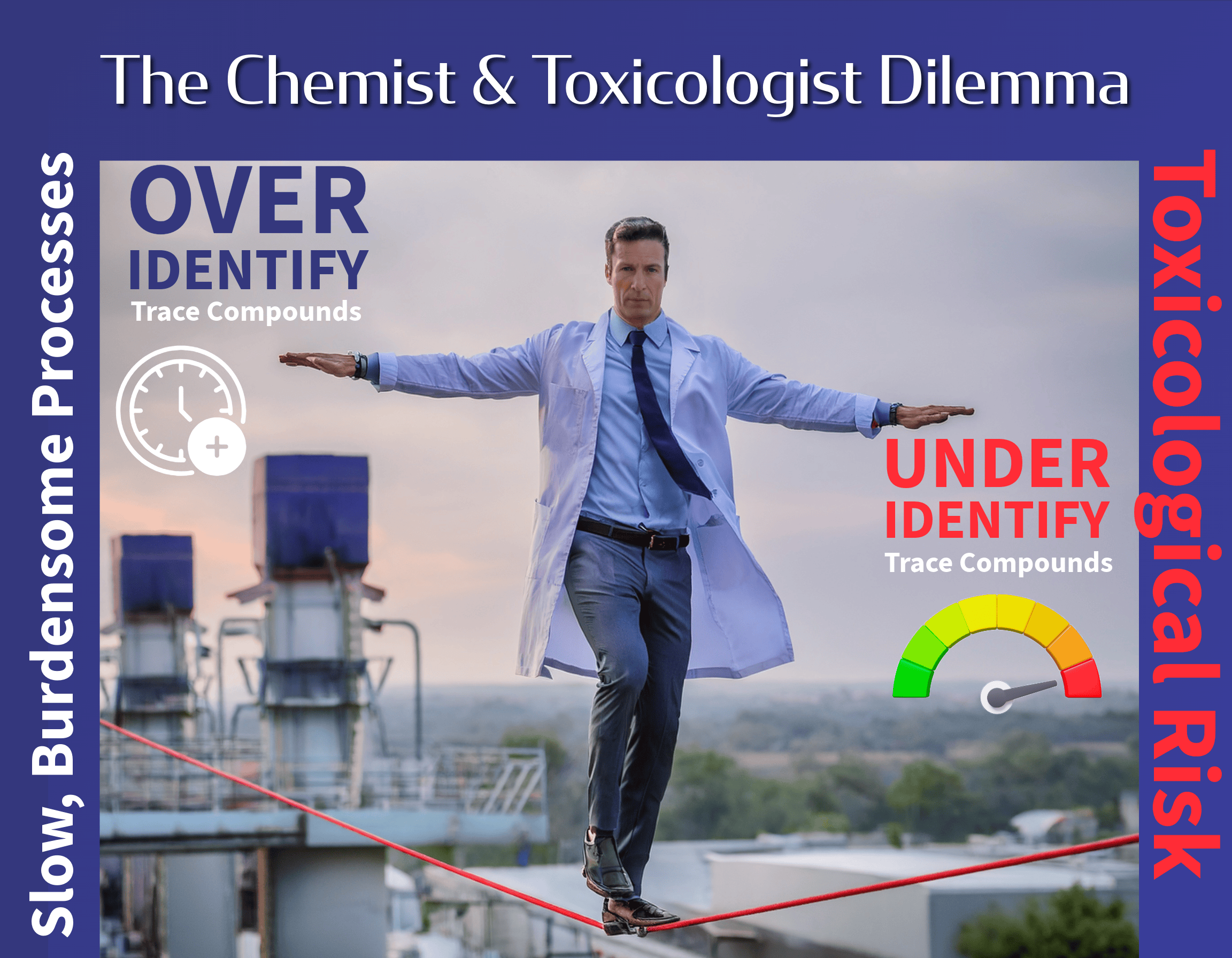

Balancing Analytical Uncertainty and Toxicological Risk Assessment

Tentative Identifications in Medical Device Chemical Characterization Analytical chemical characterization and toxicological risk assessment are essential for evaluating the risk posed by chemicals that may be present in medical devices. As detailed by ISO10993-17 and ISO 10993-18, this process can support the biological safety of a device through assessment of the toxicological risk of extractables […]

Potential Changes to the Generally Recognized as Safe (GRAS) Program

Background: The GRAS Framework The Food Additives Amendment to the Federal Food, Drug, and Cosmetic Act (FD&C Act) was established by Congress in 1958. In the Code of Federal Regulations, the rules that the FDA applies to food additives are spelled out in sections 21 CFR 170.3 and 170.30. A food additive is considered to […]

ASTM Workshop on the Characterization of Hydrogel Medical Devices: Key Takeaways

On May 6, 2025, the ASTM Workshop on the Characterization of Hydrogel Medical Devices brought together researchers and engineers to discuss current test methods for hydrogels in medical devices. Led by Stephen Spiegelberg of Cambridge Polymer Group, the workshop focused on current test methods, industry challenges, and the need for new standards. Why Are ASTM […]

ASTM Workshop on Hydrogel Characterization

ASTM International will host the Workshop on the Characterization of Hydrogel Medical Products on May 6, 2025, in Toronto, Canada, during the spring meeting of the ASTM Committee F04 on Medical and Surgical Materials and Devices. This event brings together leading experts to discuss best practices, emerging analytical techniques, and the urgent need for standardized testing methods […]