Duck, Deformulated

The ubiquitous bathtub duck, historically referred to as a rubber duck, is actually often made from plasticized polyvinyl chloride. Our scientists measured the composition of commercial bathtub ducks, investigating the base resin with infrared spectroscopy, plasticizers with gas and liquid chromatography, and fillers with energy dispersive spectroscopy. And, because it is important to know if […]

Degradation Products from In Vivo Studies

Multiple degradable thermoplastics are being used for implant or other in vivo use in the medical industry. Polycaprolactone, polylactic acid, poly lactic-co-glycolic acid and polydioxanone are just four examples of polymers that will biodegrade when placed in the body through a hydrolysis reaction. The benefits of these polymers for biomedical applications depend on their degradation […]

Notch Fatigue of Ultrahigh Molecular Weight Polyethylene (UHMWPE) used in Total Joint Replacements

CPG researcher Adam Kozak was a co-author on a recently published article in the Journal of the Mechanical Behavior of Biomedical Materials. Along with co-authors from UC-Berkeley (Ansari, Gludovatz, Ritchie, and Pruitt), these researchers investigated the sensitivity of ultra high molecular weight polyethylene (UHMWPE) to fatigue when stress concentration sites are present in the form […]

Trace Formaldehyde Detection

Formaldehyde, or CH2O, is commonly used in producing resins for coatings and adhesives, automotive materials, as well as materials for the textile industry. In these applications, the formaldehyde is normally incorporated into the material through a chemical reaction, and hence loses its chemical identity. Formaldehyde is also a by-product of some chemical reactions. Aqueous solutions […]

Microbeads in Toothpaste

Ever wonder what those little blue particles are in some toothpastes? One of our scientists did, and started to investigate their effects on teeth brushing. Known as microbeads or microplastics, these blue particles are usually polyethylene or polypropylene. They are commonly included as exfoliants in face cleansers, and may be added to toothpaste for visual […]

Why Polymer Scientists Make Great Cooks

Okay, so my wife may disagree. However, the long chain nature of a lot of food products (i.e. their polymeric nature) allows us to at least understand the physics behind the behavior of food. Cooks have known the secret of thickening sauces and gravies with a fairly small amount of flour or cornstarch. A key […]

Rubber Band-based Air Conditioners?

A common science experiment is to have a student place a rubber band against their lips while rapidly stretching the rubber band. The student will feel the rubber band heat up. Rapidly relaxing the rubber band will result in the band cooling. What is happening is that in an unstretched state, the rubber molecules are […]

Tryptophan Analysis

This time of year, our thoughts turn to tryptophan, a chemical associated with the perceived sleep-induced nature of turkey. Tryptophan is an essential amino acid (see the NH2 and COOH above), meaning that we do not naturally produce this compound, but that it is a necessary part of our diet in order for protein synthesis […]

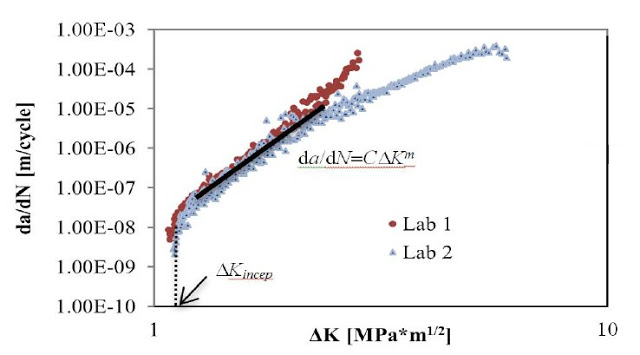

Get cracking! Fatigue crack propagation in UHMWPE

Fatigue crack propagation testing provides users information about the resistance of a material to crack initiation and propagation under cyclical loading. Currently, ASTM E647 is used to monitor the crack propagation behavior of plastic and metallic materials. Engineers at Cambridge Polymer Group have developed an automated optical system that allows real-time assessment of crack length […]

3rd Edition of the UHMWPE Handbook is Available

The third edition of the UHMWPE Biomaterials Handbook was just offered for purchase. This edition contains the history of ultra high molecular weight polyethylene and its use in hip and knee arthroplasty. The new edition contains multiple chapters addressing analytical testing techniques to characterize UHMWPE, wear testing, accelerated aging, antioxidant effects, and advances in UHMWPE […]