Chromatography: To Quantify or Not to Quantify, That Is the Question

Our chromatography team is regularly asked to identify compounds in materials. Some projects only require the identification of compounds, while others require the accurate determination of concentration of the identified compounds. The latter, termed quantitative chromatography, requires the preparation of calibration standards suitable for the compound in question. At a recent dinner, one of our scientists recognized, in an acute way, the benefit of concentration assessment over the more qualitative assessment of presence for the compound capsaicin.

Why Tails Matter

Molecular Tweaks That Determine Whether You’re Enjoying Salsa or Enduring Spider Toxins

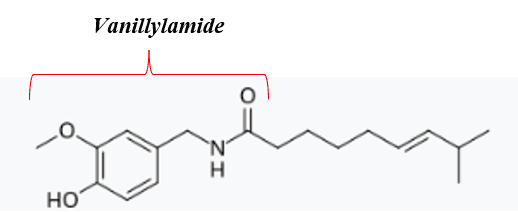

Capsaicin, or 8-methyl-N-vanillyl-6-nonenamide, is the compound found in chili peppers that provides the burning sensation in tissues with which it comes into contact. Capsaicin is the predominant compound found in the general category of capsaicinoids, shown in Figure 1. These compounds all have the same vanillylamide structure at one end of the molecule (left in the figure) but have differing aliphatic tails. Interestingly, the vanillotoxin of the venom of some tarantulas activate the same pain pathways as capsaicin, although arguably through a much less enjoyable mechanism.

Figure 1: Capsaicin compound. Common Vanillylamide group marked on the left with the unmarked tail on the right varying between compounds.

The Scoville Heat Unit

Consumers of food prepared with chili peppers instinctively know that there are levels of heat in the food that is dependent on the concentration of capsaicin. Around 1912, William Scoville, a pharmacist, developed a subjective scale to provide a ranking of the hotness of chili peppers. In his original test, a known weight of dried pepper was extracted in ethanol and diluted to specific concentrations of solutions of the extract in sugar water.

These solutions were tasted by a panel of tasters until a majority could no longer detect the heat in the solution. The heat unit was based on the amount of dilution necessary to lose the detectable heat, so a pepper requiring a dilution of 1 million times before no heat was detected would have a Scoville Heat Unit (SHU) of 1 million.

The hottest pepper tested to date is Pepper X with a SHU of 2,693,000, created in 2023 by crossbreeding the Carolina Reaper with another pepper. For comparison, a Jalapeno pepper has an SHU between 2,500-10,000.

Scoville aimed to assess capsaicin content for use in muscle salves and related pharmaceutical products. His scale became important for both culinary and pharmaceutical applications, especially in ensuring product consistency, safety, and efficacy.

Replacing Tongues with Chromatography Columns

An obvious weakness of this subjective technique is variability between tasters and sensory fatigue. To remove this subjectivity, the assessment of SHU is now performed with high performance liquid chromatography, which can quantitatively measure the concentration of capsaicinoids directly. Dried pepper samples are extracted in acetonitrile and the peak area associated with the capsaicin compound is compared to calibration curves prepared from standards. The results are free from subjective bias, and the test subjects are much happier. This approach is very similar to the trace compound analysis performed by Cambridge Polymer Group.

Capsaicin Quantification Applications

- Food Industry: Manufacturers of spicy foods, sauces, and extracts need precise capsaicin quantification for flavor standardization, product labeling, legal compliance, and quality assurance.

- Pharmaceutical/Medical Device: Companies developing capsaicin-containing topical creams, patches, or other formulations require accurate quantification during R&D, regulatory submission, and quality control for clinical use.

- Packaging: In modern packaging science, capsaicin is directly incorporated into biomaterials such as antimicrobial films, coatings, and encapsulation systems to enhance freshness, control microbial growth, and improve barrier properties for food and medical products.[1]

Capsaicin quantification is crucial not just as a safety and contamination measure, but as a technical quality parameter for new biomaterial products and advanced controlled-release systems. These advanced delivery systems still depend on robust quantitative chromatography to verify capsaicin loading, release profiles, and shelf-life performance in real formulations.[2]

Contact Cambridge Polymer Group today for expert chromatography, quantification, and material characterization services. Speak to one of our scientists to help define your product or research needs.

[1] Qincong Luo, Jinyu Ouyang, Luqi Zhan, Guohuan Liang, Xiaojuan Wang, Development and characterization of capsaicin-enriched Dialdehyde starch-PVA films for antimicrobial food packaging. International Journal of Biological Macromolecules.2025;330(Pt 1):147918. doi: 10.1016/j.ijbiomac.2025.147918.

[2] Qiu X, Xie J, Mei J. Recent Advances in the Applications and Studies of Polysaccharide-, Protein-, and Lipid-Based Delivery Systems in Enhancing the Bioavailability of Capsaicin-A Review. Polymers (Basel). 2025 Apr 27;17(9):1196. doi: 10.3390/polym17091196. PMID: 40362978; PMCID: PMC12073809.