In medical device development and surgical training, having a suitable test environment is essential for screening device concepts and reliably training surgeons. Traditionally, this process relied on excised animal or human cadaveric tissue—but the use of such tissue is problematic from both ethical and practical perspectives, including issues with stability and variability.

Hydrogel systems now offer a promising alternative: they are ethical, reliable, and mass-producible tissue models, thanks to their wide range of potential material properties. Yet, matching hydrogel properties to natural tissue is no trivial feat. Consider the simple act of cutting tissue with a scalpel: what mechanical properties are needed to achieve the correct cutting “feel”?

The Hidden Complexity of Tissue Cutting

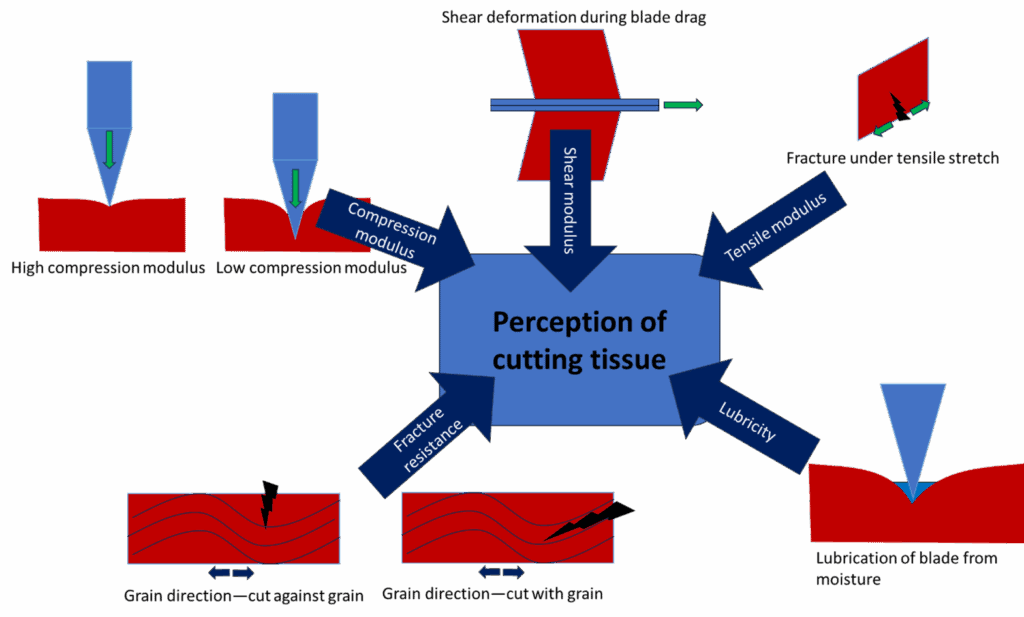

Cutting tissue with a scalpel is a surprisingly complex process, involving a delicate balance of mechanical and rheological behaviors, as well as the natural inhomogeneity of tissue. Because many tissues and organs are non-uniform, accurate mechanical testing is challenging. The most common property reported in the literature is modulus—typically in compression—but this alone cannot capture the complexity of real tissue.

Cutting is fundamental to surgical procedures, whether using a scalpel or more advanced techniques like radiofrequency ablation, laser cutting, or electrocautery. To ensure effective surgical training and device prototyping, it is crucial to replicate the appropriate “feel,” or psychorheology, of cutting natural tissue.

Beyond Modulus: The Role of Fracture Resistance and Lubricity

When a scalpel cuts into tissue, modulus is important, but it is not the only factor influencing the cutting experience. The process begins with the compression of tissue under the blade, followed by the slicing motion and ultimately the separation of tissue. The initial contact is characterized by the compression modulus: soft tissues like lung or brain may be difficult to cut due to excessive compression, while firmer tissues like cartilage or skin provide a more stable feel.

However, compression modulus alone is insufficient to predict or mimic the cutting experience. Another critical factor is the tissue’s resistance to stretching and tearing. Imagine cutting through chicken or steak: as the blade moves, the tissue is stretched (in tension and shear) until it fractures. The cutting feel depends on whether the cut is made with or against the grain.

Muscle tissue, for example, contains a fibrous network. Along the fiber direction, it is harder to stretch; perpendicular to the fibers, stretching is easier. Compression, tensile, and shear moduli all contribute to the overall cutting feel.

Cutting with the grain is generally easier, as the blade can slip between fibers to slice through softer tissue, which has lower fracture or tear resistance. Most natural tissues have a fibrous network that prevents catastrophic tear propagation—this is crucial, as it means small nicks do not become life-threatening tears.

Most natural tissues are moist and/or contain oils. The lubricity—how easily the blade moves—is affected by the presence of fluids like blood or fatty oils. If tissue sticks to the blade, the cutting action can feel dull or draggy. Lubricity is therefore another key component of the cutting experience and can be quantified through tribological measurements of the coefficient of friction in the presence of relevant lubricants.

Overview of “psychorheological” components of simple cutting of tissue.

The Challenge of Mimicking Natural Tissue

As this overview shows, even the simple act of cutting with a scalpel depends on many interrelated factors. The blade’s shape, surface energy, and roughness also play roles, but here we focus on the tissue itself. The complex structure of natural tissues is difficult to replicate with hydrogels, despite recent advances in achieving a wide range of stiffness values.

To truly mimic the feel of cutting natural tissue with a synthetic hydrogel material, it is essential to recognize the interplay between modulus, fracture resistance, and lubricity. Enhancing one property may diminish another, making this a significant challenge for material scientists and engineers.

Conclusion

The “psychorheological” experience of cutting tissue is shaped by a combination of mechanical, rheological, and structural factors. As the field advances, understanding and measuring these properties—modulus, fracture resistance, and lubricity—will be crucial for developing realistic, reliable, and ethical alternatives for surgical training and device development.

At Cambridge Polymer Group, we are committed to advancing the science of tissue simulation, helping to bridge the gap between synthetic models and the real-world demands of medical practice. If you’d like to learn more about how we can support your projects, please reach out!