At Cambridge Polymer Group, we help many of our clients evaluate their materials or device by applying accelerated aging techniques to accelerate material degradation, either for shelf life estimation or as part of an evaluation of material stability. Such testing may be performed following standard procedures like ASTM F1980, ASTM F2003, as well as custom aging studies which expose the material to specific environments which a particular product or material is expected to experience during end use. Selection of accelerated aging conditions requires careful consideration of the device composition, its materials’ properties, storage conditions, the end use environment, and the assumptions implicit in the accelerated aging calculations. As such we are always interested in test methodologies and case studies of material aging (whether accelerated or real time).

Accidental Accelerated Aging of Paper

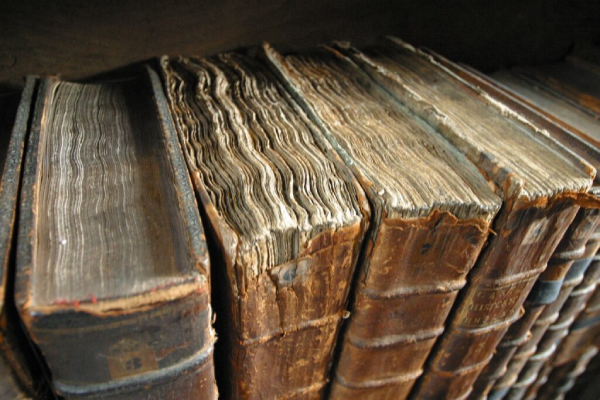

Consider the storage of paper. Paper is composed of principally cellulose fibers, which are a naturally derived polymer—a polysaccharide with D-glucose as the repeat unit. Anyone who has dug in the far back corner of the university library basement stacks or through a box of books in Grandma’s stuffy attic knows that paper is subject to yellowing, degradation, and that “old book smell”. Naturally, for important documents, steps are implemented to preserve the documents and slow the degradation process. But such mitigating practices have in some cases been counterproductive.

Lamination

Starting in the 1950s, South Carolina’s state archives and history department laminated many thousands of documents for the purpose of preserving them. Seems ok, right? Sealing the paper away from the outside environment should prevent moisture and oxygen from causing damage. Except the opposite result has been observed after many years—the laminated documents are observed to yellow and even produce the scent of vinegar. Something’s wrong!

Sheet Proximity

Similarly, researchers at the Library of Congress performing accelerated aging studies tested cases where individual sheets of paper were left exposed to the atmosphere or placed in stacks containing many sheets in close proximity. Intuitively, one may expect that the sheets more exposed to the environment would age faster due to their greater exposed surface area. The opposite result is observed—the Library of Congress study found that stacks of paper were the ones aging more rapidly. What’s going on?

The Importance of Material Chemistry

The intuitive reasoning above ignores an important potential source of degradation; the paper itself and its protective materials – whether lamination or adjacent paper sheets. Researchers at the Library of Congress have found that acids (even trace acids in “acid free” paper) from within the material stimulate acid hydrolysis of the cellulose, a byproduct of which is additional acids which cause more hydrolysis and degradation. As a result, even acid free or pH neutral papers have been observed to become increasingly acidic as they age. When such paper is laminated or stacked among adjacent sheets, such acids are allowed to build up and, counterproductively, accelerate damage to the document. It should also be noted that such acid and volatile organic compound (VOC) byproducts of the paper degradation are responsible for that “old book smell” in the university stacks (so perhaps don’t breathe too deep).

The above situations are excellent case studies on the importance of carefully considering the chemistry of the underlying material prior to making design decisions on material storage or experimental decisions for accelerated aging studies (which may yield invalid results if founded on faulty assumptions).

Do you need assistance with accelerated aging, experimental design, stability testing, or volatile organic compound analysis? Contact Cambridge Polymer Group to see how we may be able to assist your team.