Rubber band-based air conditioners?

A common science experiment is to have a student place a rubber band against their lips while rapidly stretching the rubber band. The student will feel the rubber band heat up. Rapidly relaxing the rubber band will result in the band cooling. What is happening is that in an unstretched state, the rubber molecules are randomly organized; stretching the rubber band orients the molecules, thereby reducing their entropy (state of randomness). If this is done quickly, the rubber band heats up as the heat generated internally by this decrease in entropy cannot be dissipated rapidly enough to the surrounding atmosphere. Likewise, when the entropy is rapidly increased by relaxing the rubber band, energy is consumed by the rubber band, resulting in its cooling.

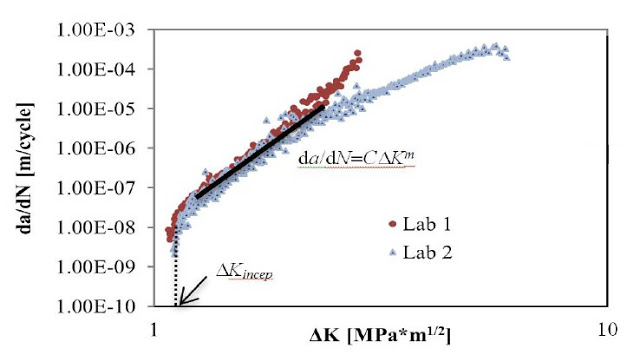

This effect has been termed the elastocaloric effect, and is being investigated as a means of providing cooling as an alternative to the typical vapor compression cycle used in most refrigerator and air conditioner units. This change in molecular level ordering can be accomplished through mechanical means, magnetic means, or electrical means (the latter two termed magnetocaloric or electrocaloric cooling). A key technological challenge is identifying materials that can handle the millions of cycles of fatigue behavior without change.

The Department of Energy is exploring these alternative technologies as part of their interest in greener building technologies. The key metric for success is an improved coefficient of performance (COP) of the new technologies (ratio of the delivered cooling energy to the total input wattage of the device) vs. existing vapor compression cycles, which are around 3-4.