Material Stability Testing: Ensuring Long-Term Product Performance

At Cambridge Polymer Group, we specialize in comprehensive material stability testing to help manufacturers ensure the long-term performance and safety of your products. Our advanced testing capabilities and deep expertise in polymer science allow us to provide critical insights into how materials behave over time under various environmental conditions.

Why Material Stability Testing Matters

Material stability is crucial for:

- Determining product shelf life

- Ensuring safety and efficacy throughout a product’s lifespan

- Meeting regulatory requirements

- Optimizing packaging and storage conditions

- Predicting long-term performance in real-world applications

Our Approach to Material Stability Testing

Accelerated Aging Studies

We conduct accelerated aging tests using elevated temperatures to simulate long-term aging in shorter timeframes. Our approach includes:

- Testing at multiple temperature points

- Careful selection of test conditions based on product specifications

- Analysis of degradation kinetics to extrapolate long-term stability

Real-Time Stability Testing

For a comprehensive understanding of material behavior, we also perform real-time stability testing under recommended storage conditions. This testing involves:

- Monitoring products until they fail specifications

- Establishing accurate shelf-life predictions

- Validating accelerated aging results

Environmental Stress Testing

We evaluate material stability under various environmental stressors, including:

- Humidity

- Light exposure (photostability testing)

- Temperature cycling

- Mechanical stress

Custom Stability Protocols

Our team develops tailored stability testing protocols to address specific product requirements and use cases, considering factors such as:

- Intended storage conditions

- Potential environmental exposures during use

- Regulatory guidelines for specific industries

Advanced Analytical Techniques

We employ a range of analytical methods to assess material changes over time:

- Fourier Transform Infrared Spectroscopy (FTIR) for chemical composition analysis

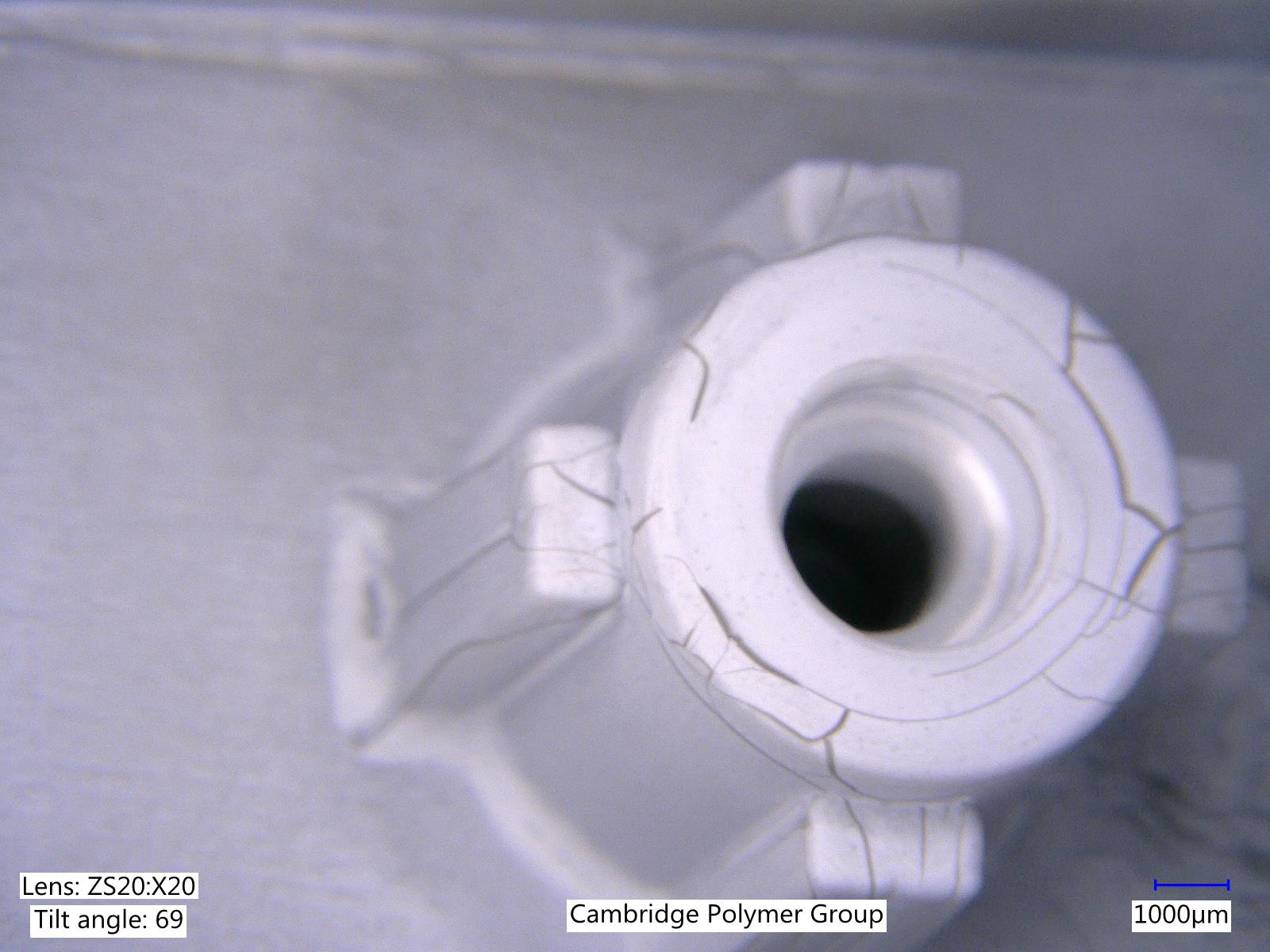

- Scanning Electron Microscopy (SEM) for surface morphology evaluation

- Mechanical testing to assess changes in physical properties

- Thermal analysis techniques (DSC, TGA) to detect alterations in material behavior

- Molecular weight changes

Comprehensive Stability Reports

Our detailed stability reports include:

- Data analysis and interpretation

- Shelf-life predictions

- Recommendations for storage and handling

- Insights into degradation mechanisms

- Suggestions for formulation or packaging improvements if needed

Why Choose Cambridge Polymer Group for Material Stability Testing?

- Expertise in polymer science and material behavior

- State-of-the-art testing facilities

- Customized testing protocols tailored to your specific needs

- Comprehensive analysis and actionable insights

- Support for regulatory submissions and compliance

Ensure the long-term stability and performance of your materials with Cambridge Polymer Group’s expert material stability testing services. Contact us today to discuss your testing needs and develop a customized stability program for your products.