Hydrogel Preparation and Characterization

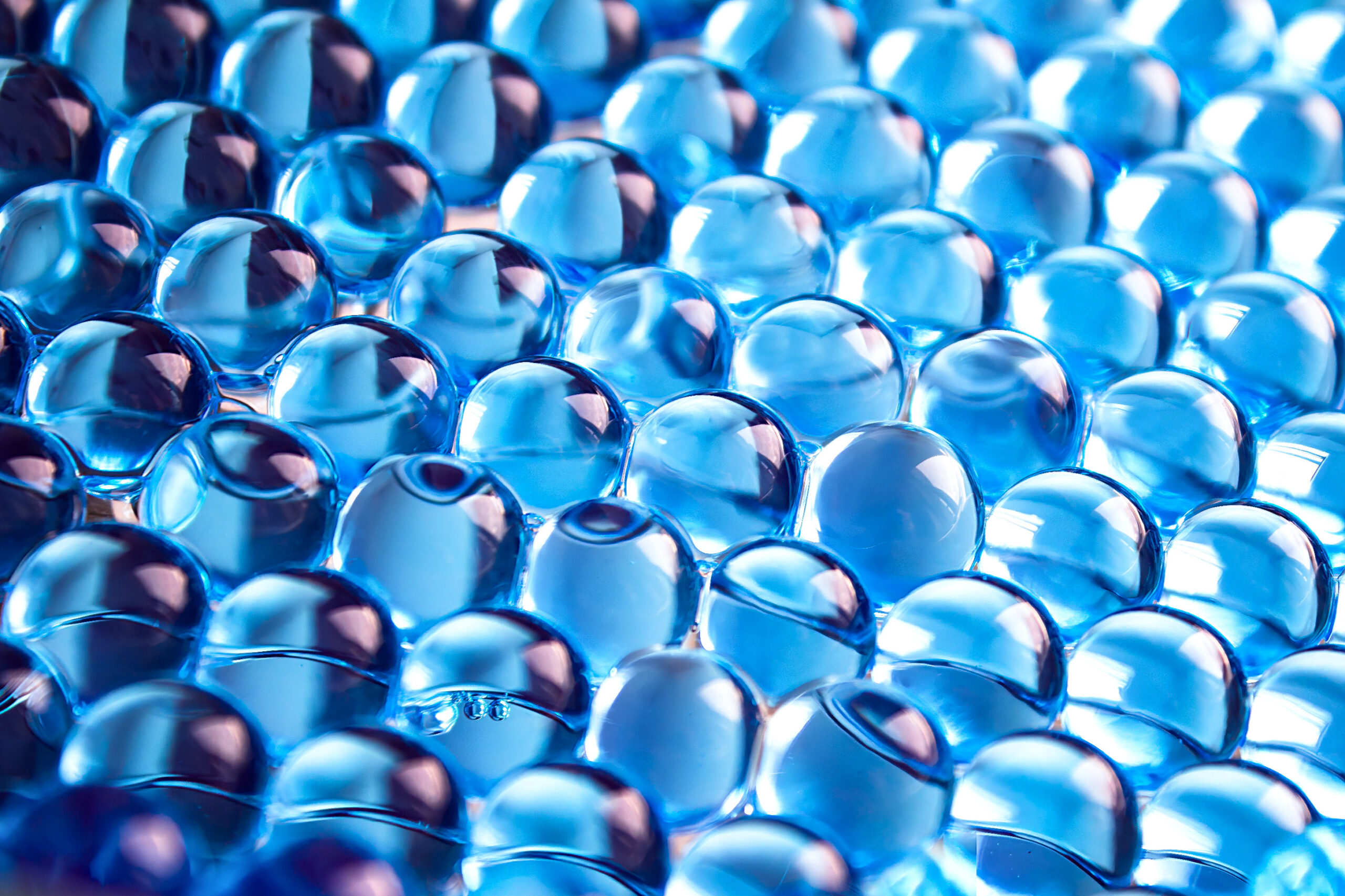

Hydrogels are an incredibly versatile class of materials, finding applications across diverse industries, including food, medical devices, pharmaceuticals, defense and beyond. These unique materials are predominantly water but have a structure or form. As a result they exhibit properties between liquids and solids and can often be designed for specific form, function, or tactile experience. Hydrogels can range from sticky, goo-like substances to stiff elastic materials, serving purposes in medicine as simple as occupying space (tissue bulking) or as complex as delivering therapeutics directly to tumors or cartilage replacement. The possibilities for hydrogels are virtually limitless, and no single formulation can address all potential applications. As hydrogels become more prevalent in commercial products, especially in medical devices, there is a strong regulatory emphasis on the characterization of their physical properties and performance.

Preparation Methods and Polymeric Networks

The preparation of hydrogels involves various techniques, each influencing the material’s properties and suitability for different applications. Common methods include physical and chemical cross-linking, free radical polymerization, and photo-initiated polymerization, but the net result is always the formation of a network of chains supporting and confining water. These networks are crucial in determining the hydrogel’s properties and applications, as they influence the material’s mechanical strength, elasticity, and swelling behavior.

Physical cross-linking involves non-covalent interactions such as hydrogen bonding, electrostatic forces, hydrophobic interactions, or simply entanglements among polymer chains, forming stable polymeric networks that can absorb significant quantities of water. In contrast, chemical cross-linking, involves chemical bonding between the polymer chains, resulting in more robust and durable hydrogels. This method is often used when a stronger material is required, such as in load-bearing applications or where long-term stability is needed. The choice of preparation method depends on the intended application and desired properties of the hydrogel.

A further unique aspect of these materials is that the nature of the final crosslinked network depends on how the hydrogel was crosslinked. If it is crosslinked in a confined state, the network becomes tightly bound and the swelling is limited, whereas if the network is crosslinked in a dilute state the network is essentially fully swollen.

Hydrogel Applications

One of the defining characteristics of hydrogels is their ability to absorb and retain large quantities of water, which can be up to several hundred times their dry weight. This high water content imparts unique properties to hydrogels, such as biocompatibility, solute permeability, flexibility, and the ability to mimic natural tissue, making them ideal for a wide range of applications. In the medical field, hydrogels are used in wound dressings, drug delivery systems, and tissue engineering scaffolds. Their ability to conform to the shape of a wound and maintain a moist environment promotes healing and reduces pain.

In the food industry, hydrogels serve as thickeners, gelling agents (Jello®, for example), and moisture retainers, enhancing the texture and shelf-life of various products. Hydrogels are also employed in environmental applications, such as water purification and soil conditioning, due to their ability to absorb and release water. In electronics and medical sensors, hydrogels are being explored for use in flexible sensors and actuators, capitalizing on their conductive properties when combined with conductive polymers or nanoparticles.

Hydrogel Characterization and Testing

The characterization of hydrogels is essential to ensure their performance and safety in various applications. Currently, the standard test methods for hydrogel materials are limited. While hydrogels may be formulated to exhibit qualities similar to elastomers, rubbers, or plastics, standard tests for these materials often do not apply to hydrogels due to their unique properties.

At Cambridge Polymer Group, we specialize in developing custom test methods tailored to capture the desired performance characteristics, in modes that are relevant to the end-use, of your hydrogel products while adhering to regulatory expectations.

Since hydrogels primarily consist of water, their intended use often requires or provides moisture. We offer comprehensive immersion rheological and mechanical testing to evaluate hydrogel properties under normal use conditions. This testing is crucial for understanding how hydrogels will perform in real-world environments, ensuring their reliability and effectiveness.

For implantable medical devices, hydrogel materials physically respond to their local physiological environment, often by swelling or shrinking. This process can be driven by temperature or solvent conditions and is often the key benefit of the material for use in sensors. Such fluctuations in hydrogel size can exert force on neighboring tissues and organs, a growing concern for regulatory bodies like the FDA. To address this, Cambridge Polymer Group offers swell pressure testing to measure the force exerted by swelling hydrogels, providing critical data for ensuring the safety and compatibility of these materials in medical applications.

Another area of interest arises from the permeability of the hydrogels. Because these materials are predominantly water, they allow salt diffusion while at the same time trap and confine other species. This allows these materials to have complex electrical properties such as conductivity and permittivity, of relevance for medical devices utilizing electrical currents, or high frequency radio waves. Cambridge Polymer Group can test for these parameters to match performance requirements or tailor formulations for specific end-uses.

Our comprehensive approach to hydrogel characterization includes a variety of advanced techniques, including swell ratio testing (SRT), differential scanning calorimetry (DSC), thermal gravimetric assessment (TGA), gel permeation chromatography (GPC), atomic force microscopy (AFM), and scanning electron microscopy (SEM). By employing these methods, we can provide a detailed understanding of the hydrogel’s structure, properties, and potential applications.

Synthetic vs Organic Hydrogels

Hydrogels are defined by the type of polymers they are made of, which can be artificial, organic, or a combination of both. Natural polymers are particularly beneficial in biomedical applications because they are biodegradable and non-toxic. In contrast, synthetic polymers offer hydrophobic properties with strong covalent bonds, providing durability and mechanical strength. Understanding these differences is key to designing hydrogels with the desired performance, structure, and shelf-life.

Synthetic Tissue Models

With increasing pressure to reduce dependency on animal or cadaveric testing for surgical tools, hydrogels offer many physical characteristics similar to tissues and organs. Cambridge Polymer Group provides custom hydrogel formulation and tissue model fabrication, guided by your specific physical and performance criteria. Our services enable the development of realistic and effective models for testing and training purposes.

Why Choose CPG for Your Hydrogel Needs?

At Cambridge Polymer Group, we are committed to advancing the field of hydrogel technology through rigorous characterization and innovative solutions. Our team of experts is dedicated to helping you achieve your goals by providing tailored testing and development services that meet the highest standards of quality and compliance.

Contact us today to learn more about how we can assist you in harnessing the full potential of hydrogel materials for your specific applications. Let us help you navigate the complexities of hydrogel characterization and preparation to achieve success in your product development efforts.