“Robotics” covers a broad spectrum of devices, from industrial robots common in automotive manufacturing or autonomous vehicles, to medical robots used to perform or aid surgeries, and to collaborative “cobots” designed to help and support human activities. Common material issues for robotics include durability and wear, strength-to-weight optimization, and material aging. Environmental exposures such as extreme temperatures and pressures, corrosive chemicals, radiation, and aggressive cleaning agents can significantly shorten a robot’s lifespan if not considered during design and material selection.

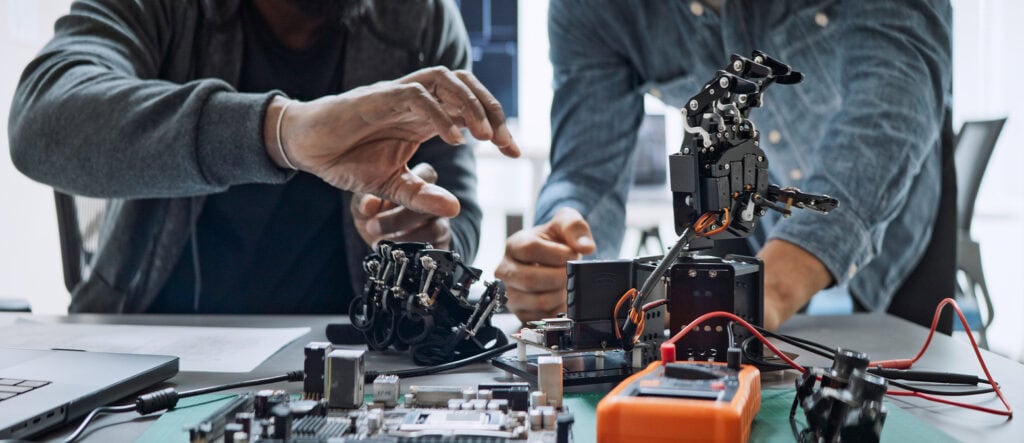

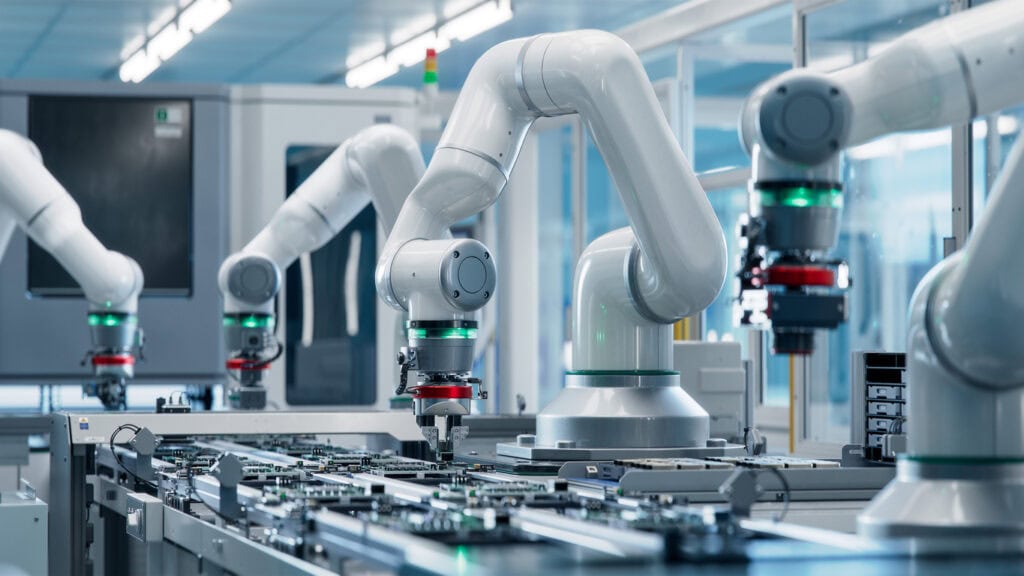

Traditional Robotics Materials

Traditional robot design employs electromechanical motors to control movement, with separate components for sensing movement and contact. These components are typically encased in housings to provide structural support and environmental protection. In these designs, each component usually has a single function, and the materials used range from standard metals to thermoplastics and composites, processed using standard milling, drilling, molding, or related techniques. Polymers are common choices in many functional areas because of their excellent strength-to-weight ratios and favorable wear and chemical-resistance properties.

Soft Robotics Materials

The emerging field of soft robotics is particularly important in applications that involve close interaction with people, including many medical, wearable, and assistive systems. These robots often use servohydraulic or pneumatic actuators or environmentally responsive materials to create constructs that can change shapes in ways that conventional electromechanical systems cannot. Through the use of soft polymeric materials, lighter weight and more anatomically relevant robots can incorporate components that combine movement and sensing, or that present specific surface chemistries to dynamically change wettability or adhesion properties.

Robots made from soft materials usually require different manufacturing processes from traditional robot designs, and the choice of processing conditions can influence performance capacity. The materials used in soft robotics include elastomers, hydrogels, organogels, textiles, and materials derived from biological sources, each with distinct mechanical, chemical, and aging behaviors that must be understood for reliable use.

How Cambridge Polymer Group Helps

Cambridge Polymer Group’s experience with soft solids, environmental aging, material design and general material testing helps robotics teams select and verify materials for both rigid and soft robotic systems. This experience extends from early‑stage concept evaluation through to qualification of production materials under realistic mechanical and environmental loads.

Our support can include identifying candidate polymers and gels for specific operating environments, defining test plans to probe durability, wear, and stability, and interpreting results to guide design refinements. For soft robotic components in particular, CPG helps relate formulation, processing conditions, and aging behavior to performance metrics such as actuation range, force output, and long‑term reliability.