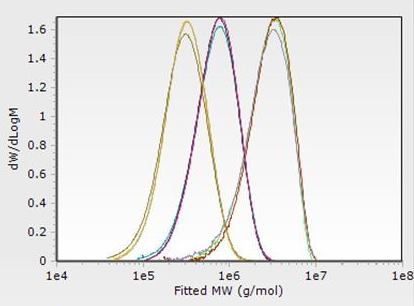

Pharmaceutical excipients are inactive substances added to pharmaceutical products for purposes other than a direct therapeutic effect. These materials are added to enhance function, or usage or stability. A sub-class of these materials are the polymer-based excipients. Unlike salts and small molecule excipients, the behavior of polymeric excipients can be complex, requiring different testing modes and a deeper understanding of the behavior of these materials when dissolving, and in solution. The molecular weight distributions (see below), for example, becomes a critical parameter to measure and can directly inform differences in material functionality. Although these materials are typically added for a variety of functional purposes, the most common roles in pharmaceutical formulations are as disintegrants/drug delivery vehicles, fillers/binders, viscosity modifiers, and coatings. Below we discuss each topic in more detail.

Disintegrants

Disintegrants such as cyclodextrin are added to allow the tablet or capsule to break apart and dissolve and release the active pharmaceutical ingredient (API) in a controlled manner. The chemical nature of the disintegrant as well as properties such as the polymer’s molecular weight may be tuned to affect the rate at which the tablet or capsule dissolves and breaks apart and therefore affects the release kinetics of the API.

Drug Delivery

Polymers used for drug delivery such as polycaprolactam essentially play a similar role to that of disintegrants, but rather than dissolving, break down over a significantly longer period of time. This type of disintegration (degradation) allows for extended drug delivery to occur over durations of days to weeks or even months and may be localized in a specific site for a more targeted drug release. As with disintegrants, the polymer properties, such as molecular weight and chemistry, as well as overall device morphology, may be tuned to modify the API release kinetics and overall residence time of the polymer.

A related topic is that of hydrogels. These unique materials are a special class of materials that can serve as vehicles for drug delivery. Their highly hydrated, porous network nature allow for APIs to elute from the matrix at a rate that may be tuned depending on the hydrogel chemistry, the crosslink density (size of the pores), overall morphology, degradation kinetics, and affinity for the API itself. These tremendously powerful materials are a special focus of Cambridge Polymer Group, and tailoring their behavior requires a deep understanding of polymer chemistry and solubility phenomena.

Fillers and Binders

Polymer based fillers/binders such as methyl cellulose or polyethylene glycol are added to a formulation to maintain mechanical integrity during packaging, shipping, and handling. They also allow for APIs which are provided at very small quantities to be effectively “diluted” into a larger capsule or tablet form for ease of handling. It is therefore critical that these passive fillers release the drug over the time scale required for the indication.

Viscosity Modifiers

Polymer based viscosity modifiers such as hyaluronic acid or hydroxyethyl cellulose are added to liquid pharmaceutical formulations to prevent APIs from precipitating or settling out of solution—ensuring the API is uniformly dispersed throughout the liquid product. These materials also control how the solution handles to the end user. For example, a low viscosity solution would be perfect for a spray application (e.g., for nasal sprays) but would be inadequate for a topical ointment. Tracking the rheological properties and molecular weight distributions of such polymer solutions yields valuable, actionable information about the efficacy and stability of these formulation components.

Coatings

Polymer based coatings such as gelatin protect the formulation until it is needed. For example, coatings can be used to prevent premature tablet dissolution, for example the coating may be “triggered” by gastric acid pH allowing the tablet to pass through the upper digestive track prior to releasing its contents. Coatings can also be used to protect the tablet from mechanical damage and can further modify API release kinetics and can also be pigmented or labeled for tablet identification purposes.

How CPG Can Help

Cambridge Polymer Group can help your team characterize such polymer based excipients in the context of your overall product and process constraints. Such characterization may include:

- Identifying critical material properties for your application

- Raw material characterization or certificate of analysis verification

- Molecular weight analysis

- Residual solvent analysis

- Lot comparison

- Impurity characterization

- Thermal, mechanical, or spectroscopic analysis

Contact us to reach one of our experts today.