Most traditional machined components involve starting with a standard block of material, and then machining away material to form the final finished device. The advent of 3D printing systems has allowed the opposite approach to machining, where material is sequencing added to a part, in effect growing it from raw material with little scrap material generated, hence the term ‘additive manufacturing’. 3D printing allows generation of more complex geometries, such as porous structures, fully-enclosed hollow features, and finer structure than may be achievable with more conventional milling, lathing, or molding processes. Additionally, 3D printing provides the opportunity for patient-specific implants derived from X-rays or MRIs of the patient’s anatomy.

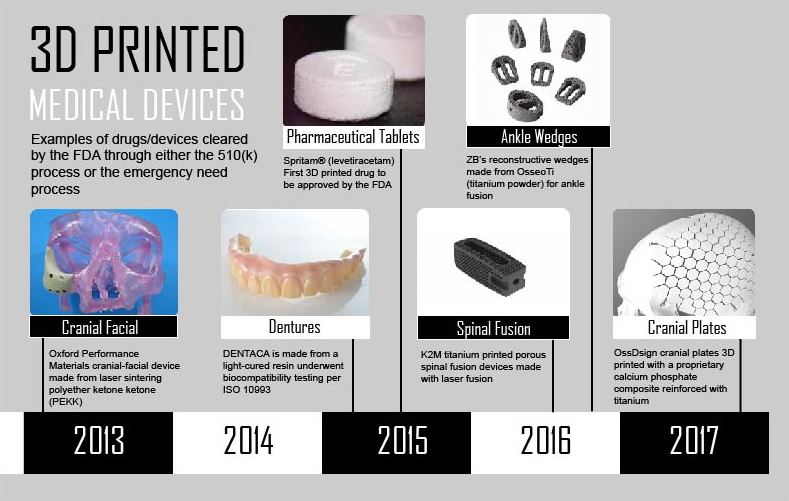

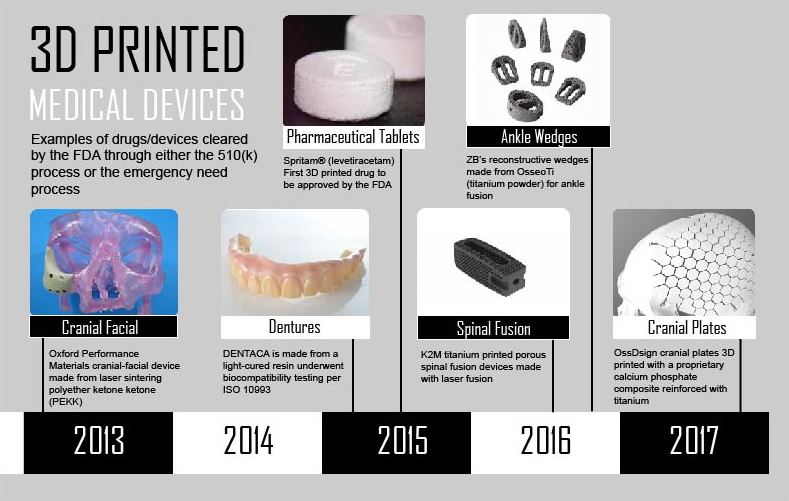

A variety of materials have been used for 3D printed medical devices, including titanium powder and its alloys, calcium phosphate powder, thermoplastics such as polyether ketone ketone, and UV or light-curable resins. Since 2013, the FDA has been clearing medical devices and drugs made from 3D printing technologies through either the 510(k) process or the emergency need process. In the 510(k) process for a device, a device is cleared by the FDA if it is shown to be as safe and effective as a legally marketed predicate device to which it is substantially equivalent (same intended uses, comparable design and materials). The same tests conducted on machined or molded devices required for clearance, such as biocompatibility, leachables/extractables, mechanical behavior, cleanliness, and functional performance, all apply to 3D printed devices, and currently no additional regulation specific to 3D manufacturing has been established. As of 2016, more than 85 devices manufactured using 3D manufacturing processes have been cleared by the FDA.

3D Printed Medical Devices

Some examples of 3D printed devices that were cleared are shown below, spanning a variety of medical application areas.

2013

- Oxford Performance Materials received 510(k) clearance for a 3D printed cranial-facial device made from laser sintering polyether ketone ketone (PEKK), granted in 2013.

2015

- DENTCA, a 3D printed denture system, received 510(k) clearance in July of 2015. DENTACA is made from a light-cured resin, and underwent biocompatibility testing per ISO 10993, in addition to human mouth tissue sensitivity contact.

- The first 3D printed drug to be cleared by the FDA was Aprecia Pharmaceuticals Co.’s epilepsy drug, Spritam® (levetiracetam) tablets in 2015. Spritam is for treating seizures in patients with epilepsy, and is printed using a method called ZipDose technology, which produces a porous pill that dissolves rapidly with liquid.

- MedShape received 510(k) clearance on a Ti6Al4V 3D printed bunion correction system in 2015.

2016

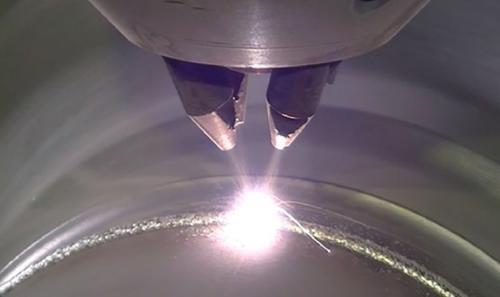

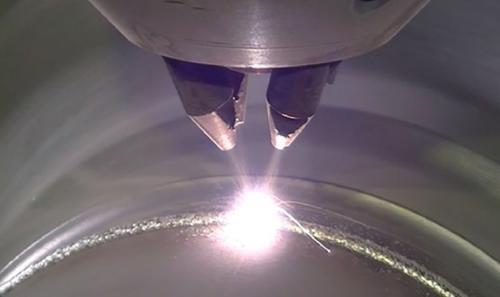

- K2M received clearance for titanium printed porous spinal fusion devices made with laser fusion, designed to have surface roughness with feature sizes of 3-5 microns to encourage bone on-growth.

- Stryker received 510(k) clearance for a titanium printed lumbar cage to treat degenerative disk disease.

- ZB’s reconstructive wedges made from OsseoTi (titanium powder) for ankle fusion received clearance.

- Additive Orthopedics cleared for titanium 3D printed devices for foot applications.

- Bioarchitects received clearance for 3D printed titanium craniofacial implants.

2017

- OssDsign received 510(k) clearance for cranial plates 3D printed with a proprietary calcium phosphate composite reinforced with titanium in 2017.

The Future of Additive Manufacturing

3D printing of drugs could allow hospitals to customize the API dose in each tablet for individual patients, ushering in a new era of personalized medicine. Additive manufacturing may also make medication easier to swallow, both for adults due to improvements in swallow-ability and dissolution, and for children, in that the drug can be made in kid-friendly shapes. At this point, conventional large scale manufacturing continues to be more financially efficient for large quantities of medication, and FDA clearance of 3D manufactured drugs is not easy to obtain.

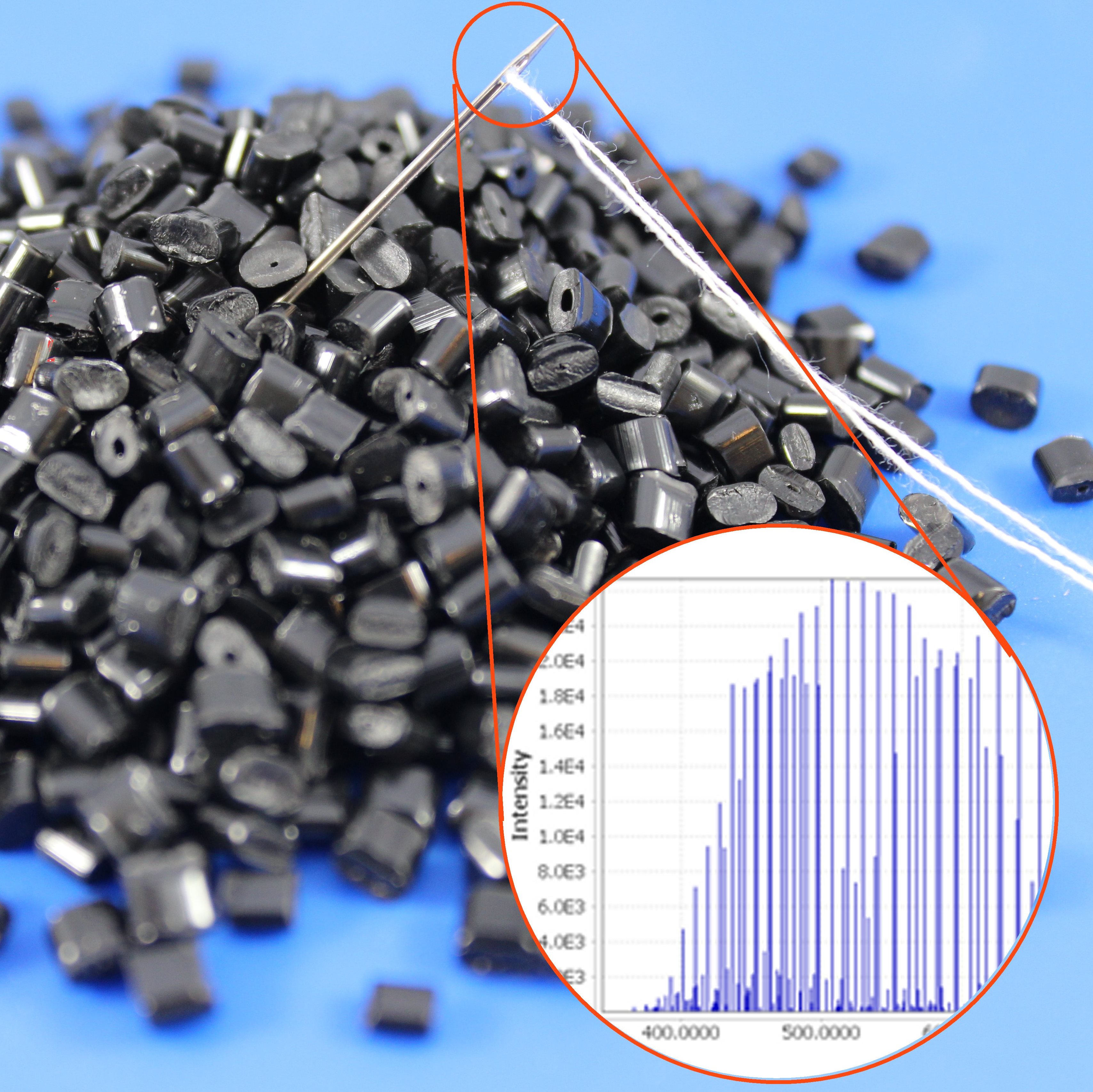

Additive manufacturing is becoming a more viable alternative manufacturing process for medical devices, since it offers solutions to designs that are unprocessable by conventional manufacturing approaches, readily allows custom device manufacturing, and may present options for on-demand manufacturing of implants. In addition to the standard tests for new medical devices, the areas that currently need addressing for additive manufacturing include process validation procedures and qualification of raw materials (new and potentially used).

Vitrum Flexile, or flexible glass. Although lost in legend, three different authors provided an account of a glass that could be dented and then repaired in Rome’s first century. According to the

Vitrum Flexile, or flexible glass. Although lost in legend, three different authors provided an account of a glass that could be dented and then repaired in Rome’s first century. According to the

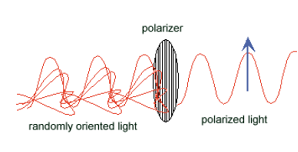

Figure 1: Schematic of randomly oriented white light passing through a polarizer, becoming plane-polarized light with the principle axis indicated by the blue arrow.

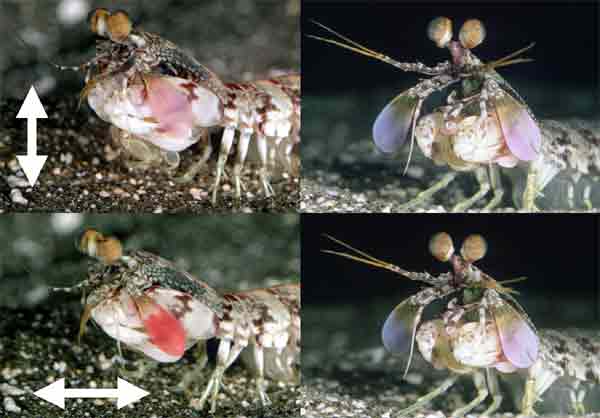

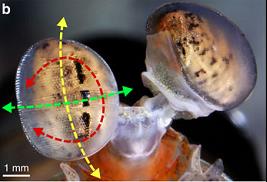

Figure 1: Schematic of randomly oriented white light passing through a polarizer, becoming plane-polarized light with the principle axis indicated by the blue arrow. Figure 2: Rotational degrees of freedom in Odontodactylus cultrifer.

Figure 2: Rotational degrees of freedom in Odontodactylus cultrifer.